It took about 14 total hours of machine time to print the parts, not counting failed prints. I used PSU LID's Ultimaker 2 and Mojo printer from Stratsys. In the end the only finished parts I got out of our Makerbot were the feet. That is longer, apparently, than our Makerbot or the Makerbot 2X's at Ctrl-H could stay in tune, and the prints failed either in the plastic extrusion, bed adhesion, or bed leveling which caused layer adhesion issues. I had a heck of a time printing, since the main microscope body takes 5-7 hours to print at low-medium resolution. I'm not going to go step-by-step through the instructions here, I'm just going to highlight some issues I had and design suggestions for the microscope and instructions. There is a part missing from the list, the "rear foot", which I hacked together from one of the regular feet and a couple of rubber bands (below). The instructions suggest (kind of buried) that the dovetail joints between the microscope body and lens assembly and light holder will work better if the small parts are not printed one at a time, but instead printed all together, because it slows the layers cooling and produces more accurate parts. ~40 ohm resistor (or two 22 ohm resistors in series).6x rubber bands 1mm cross section by 15cm unstretched.Notes on the instructions’ parts list: you don’t need hex-head m3 screws and I couldn’t find those in US hardware stores. The instructions are still in an early stage, I suggest you read them completely before assembly. I downloaded the instructions and was able to open them in Firefox. I started from the first draft instructions up on Docubricks. It will also be used by the WaterScope group for similarly sized samples for bacteria counting. While the area of the slide stage is only 4x4x8mm, that is plenty of space to analyze the small samples we'll use. This is a brilliant mechanical re-imagining of a microscope's parts around 3D printing and flexible plastic joints, or "live hinges" as they're called in plastics manufacturing.

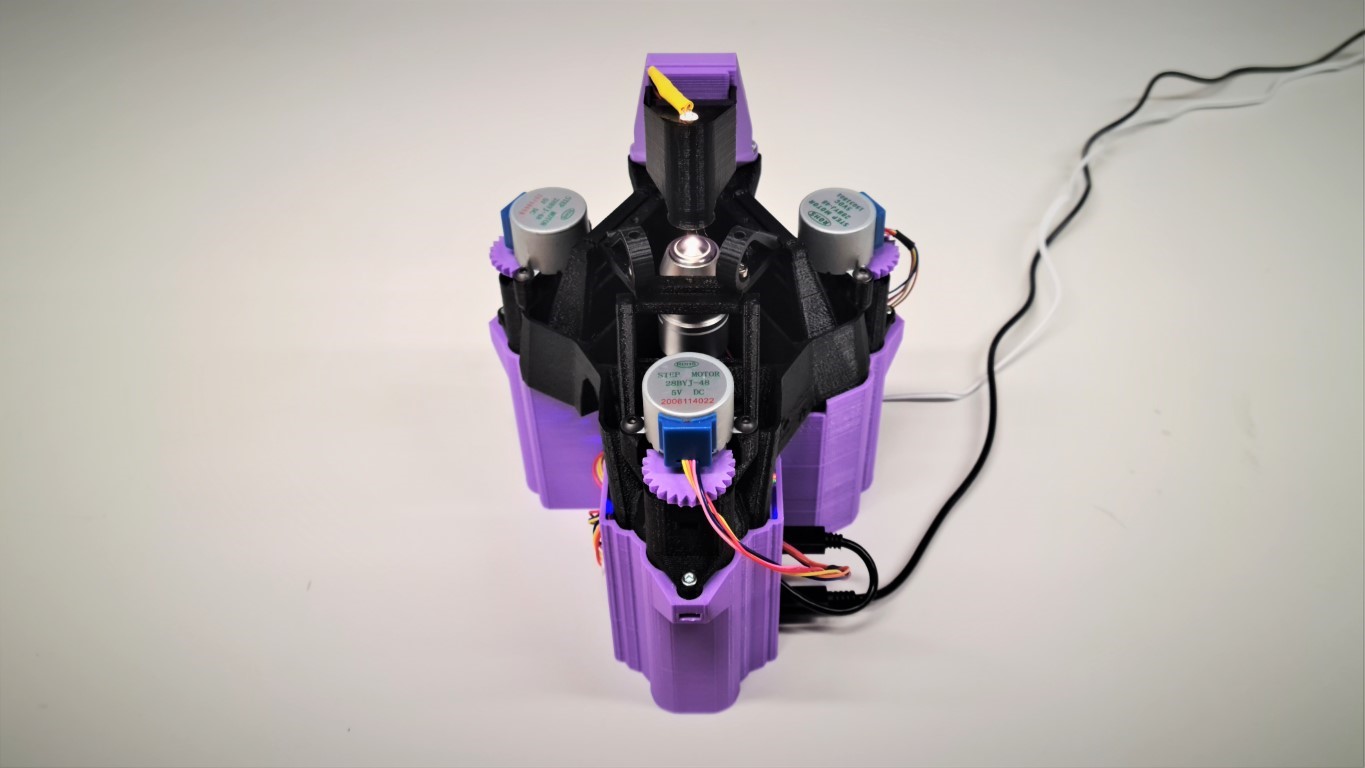

These flexing plastic joints give extremely good stability and smooth motion to the slide stage, reducing the difficulty of manufacturing dramatically. The OpenFlexure microscope replaces almost all meshing geared parts in an automated slide stage with four-bar linkages that print in a single 3D print without supports.

#Open flexture software

This microscope is the second part, along with ImageJ software automation What make the OpenFlexure microscope so cool? I’ll round out by discussing the next stage modifications to the OpenFlexure microscope to add a higher magnification lens and motorize the slide stage. In this note i’ll describe how I replicated an early version of this 3D printed microscope and slide stage, my experiences, assembly issues, and suggestions.

Determine if The Open Flexure microscope can replace expensive lab microscopes in the analysis of Passive PM monitors.

0 kommentar(er)

0 kommentar(er)